-

Мобильная дробилка

- как открыть стеклянную мельницу

- поставщик оборудования для добычи флюорита

- дробилки вальцовые или молотковые

- производство и реализация медного порошка

- камень цена дробилка в россии

- мельница для руды и угля

- дробилка завод восточный

- конус дробилки производители

- дробленого кварца для продажи

- химического гипса в цементной промышленности

- крупный шлифовальный станок

- источники загрязнения фрезерной промышленности

- стоимость проекта завода по обогащению фосфата

- оборудование необходимое для добычи кварцевого песка

- Фрезерный станок для продажи в Малайзии

- поставщиками гранита дробилка в Узбекистане

- автоматические линии для производства мозаики

- цена мельница дробилка

- оборудование и материалы для производства механического песка

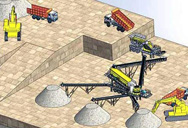

- bauxite processing plant

Physical Bauxite Processing: Crushing and Grinding of Bauxite

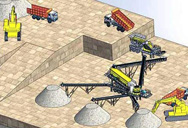

2022.1.23 The most common initial process step to feed an alumina refinery with bauxite is the crushing or sizing of the raw bauxite material that is extracted from the mine. The feed material is crushed or sized so that it is conveyable, as well as correctly

Read More

Bauxite Beneficiation Tailings Reprocessing

4 天之前 Processing: The commonly used beneficiation processes for bauxite are ore washing, flotation, magnetic separation, chemical beneficiation, etc., and the tailings can be treated by processes such as

Read More

Global Mass Balance of Bauxite Production Chain

2024.4.18 The former Vale’s bauxite processing plant, located 60 km from Paragominas, Brazil, was commissioned in March 2007. The plant receives raw bauxite ore from an open-pit mine, and performs a set of

Read More

Bauxite Processing Plant-SBM Industrial Technology Group

2024.4.1 Bauxite Processing Plant. Bentonite Processing Plant, Bentonite Grinding Mill. Talc Processing Plant, Talc Crushing and Grinding Equipment. Marble Grinding Mill,

Read More

(PDF) Chemical Processing of Bauxite: Alumina

2022.1.23 PDF This Chapter provides an introduction to the Bayer process and how the mineral composition of bauxites affects the process variants and the... Find, read and cite all the research you...

Read More

Mining and Refining – Process - International

The process stages are: 1. Milling. The bauxite is washed and crushed, reducing the particle size and increasing the available surface area for the digestion stage. Lime and "spent liquor" (caustic soda returned from the

Read More

Physical Bauxite Processing: Crushing and Grinding of Bauxite

2022.1.23 Abstract. The most common process step to feed an alumina refinery with bauxite is sizing of the raw bauxite material that is extracted from the mine. The first

Read More

Physical Bauxite Processing: Crushing and Grinding of

2022.1.23 To process the bauxite, the bauxite must be mined, crushed, and delivered to the refinery. The first step to reaching the refinery after mining the bauxite is crushing.

Read More

Bauxite Mining and Alumina Refining - PMC - National

2014.5.8 Abstract. Objective: To describe bauxite mining and alumina refining processes and to outline the relevant physical, chemical, biological, ergonomic, and

Read More

Bauxite Processing Handling Equipment

2024.2.13 EQUIPMENT. FEECO offers a variety of custom equipment and process solutions for the processing of bauxite. From processing bauxite for use in aluminum production, refractory, or

Read More

Vedanta Aluminium patents innovative breakthrough in bauxite

2023.11.6 This containment method prevents bauxite residue from inadvertently leaching into the groundwater. For this processing purpose, the company was the first in the country to establish a Bauxite Residue Processing Plant. With the new method implementation, this residue generation will be reduced further.

Read More

Impacts of greenwaste biochar on ammonia volatilisation from bauxite ...

2012.10.3 Background and Aims The objective of this study was to test the suitability of greenwaste biochar to aid nitrogen (N) retention in rehabilitated bauxite-processing residue sand (BRS). Methods Bauxite residue sand was collected from the Alcoa of Australia Pinjarra refinery. The pH of BRS was adjusted to values of 5, 7, 8 and 9 and

Read More

Alumina processing - Metso

Our alumina processing offering is based on our proven, reliable proprietary equipment portfolio and our comprehensive service expertise. We provide complete solutions for alumina refineries from bauxite to alumina, as well as plant upgrades. We are committed to innovation and continuous improvement and have a strong track record, having served ...

Read More

The Bayer Process: From Bauxite to Aluminum Hydroxide

2022.11.4 In the Bayer process, the basis for this is the different chemical solubility of the various oxides in caustic soda NaOH. Since the process is quite complicated, we will only mention the most important process steps here. The diagram of the process is shown in Fig. 20.2. The corresponding equipment in the aluminium oxide plant is marked in Fig ...

Read More

(PDF) Chemical Processing of Bauxite: Alumina and Silica

2022.1.23 The Bayer process is a chemical process for refining aluminium hydroxide, Al(OH) 3 from bauxite; this aluminium hydroxide is subsequently calcined to produce alumina, Al 2 O 3 . The basis of the ...

Read More

Bauxite Ore Processing Bauxite Ore Processing Equipment

About us. We,Star Trace Pvt. Ltd., established our operations in the year 1991, as one of the glorious ISO 9001:2008 certified manufacturers, exporters and suppliers of an unlimited collection of Industrial Separators Magnetic Equipment. Our product collection comprises of Magnetic Separators, Overband Magnets and Magnetic Roll Separators ...

Read More

Wet processing equipment CDE Asia

Read More

PT ANTAM Tbk Bauxite

Bauxite, the raw material for the production of alumina, was first discovered in 1924 at Kijang, Bintan Island, in the province of Riau, in northwestern Indonesia. Bauxite from Bintan Island has been mined and exported since 1935. In 1968 ANTAM acquired the mine. Thus, ANTAM is Indonesia's longest running producer of bauxite.

Read More

Hydro Partners with Wave to Recover Minerals from Red Mud

2023.2.22 Hydro’s Alunorte alumina refinery signed a contract with Wave Aluminium to build a plant in Brazil that will work to address the challenges of bauxite residue — also known as red mud. The new plant will process bauxite residue, aiming to recover commercially valuable materials. Bauxite residue is generated after the bauxite ore has

Read More

The processing of high silica bauxites - ScienceDirect

2009.8.1 The Bayer process is the principal method for the production of alumina from bauxite worldwide. The modern version of the process (developed in the 1880's) still maintains the key steps of dissolution of alumina-rich minerals into hot caustic solution, separation of the insoluble phases, followed by gibbsite precipitation and calcination of

Read More

Bauxite Processing Residue: A Critical Review of Its

2011.2.2 Abstract. Bauxite is processed in alumina refineries by the Bayer process in which Al-containing minerals are dissolved in hot NaOH. The insoluble solids (bauxite processing residue mud and sand) are washed, sometimes partially neutralized (using CO 2 or seawater treatment), and deposited in impoundments surrounding the refinery using

Read More

Global Mass Balance of Bauxite Production Chain

2024.4.18 The former Vale’s bauxite processing plant, located 60 km from Paragominas, Brazil, was commissioned in March 2007. The plant receives raw bauxite ore from an open-pit mine, and performs a set of

Read More

Surface charge characteristics and sorption properties of bauxite ...

2010.3.19 Bauxite-processing residue sand (BRS) is the primary growth medium used to rehabilitate Alcoa’s residue storage areas (RSAs) in south-west Western Australia. This material is typically coarse-textured, highly saline, highly alkaline, extremely sodic, and deficient in plant nutrients. To develop appropriate fertiliser strategies for optimising

Read More

Rotary Kiln Calcination Plant - Dolomite Calcination Plant

2 mt/hr up to 50 mt/hr. We stand as one of the leading manufacturers of Calcined Bauxite Rotary Kiln, manufactured from superior quality of raw materials. Some of the attributes of these machines are durability, robust, efficiency and cost effectiveness.These are fired with Petcoke, Oil, Gas and Coal Gas. We also provide dual fire option as well.

Read More

Crushing plant for bauxite processing sale in jamaica - LinkedIn

2023.11.30 The bauxite ore processing and crushing plants in Jamaica are integral to the island#8217;s economy and the global aluminum supply chain. Through efficient processing and responsible mining ...

Read More

Bauxite Ore Processing Bauxite Ore Processing Equipment

About us. We,Star Trace Pvt. Ltd., established our operations in the year 1991, as one of the glorious ISO 9001:2008 certified manufacturers, exporters and suppliers of an unlimited collection of Industrial Separators Magnetic Equipment. Our product collection comprises of Magnetic Separators, Overband Magnets and Magnetic Roll Separators ...

Read More

Bauxite Calcination Plant at Rs 8000000/piece Bauxite Processing ...

Bauxite Calcination Plant - Buy Bauxite Processing Plant at best price of Rs 8000000/piece by Kinc Mineral Technologies Private Limited. Also find product list from verified suppliers with contact number ID: 2532978448

Read More

Review on treatment and utilization of bauxite residues in

2009.12.8 Bauxite residue (red mud) is a solid waste produced in the process of alumina extraction from bauxite. More than 70 million tons of bauxite residue is generated annually. Presently, it is stored on land or in the ocean near alumina refineries. However, its high alkalinity is a potential pollution to water, land and air of close proximity.

Read More

Mining and Refining – Process - International

Bauxite is generally extracted by open cast mining, being almost always found near the surface, with processes that vary slightly depending on the location. Before mining can commence the land needs to be cleared of

Read More

Soil pollution and toxicity in an area affected by emissions

2019.4.15 Soil pollution and toxicity have been investigated in the Gardanne area (southern France) at a range of sites around a recognized pollution source, a bauxite processing plant (BPP), and a power plant (PP). Soil samples were submitted to inorganic and organic analyses and tested for toxicity in two invertebrate models.

Read More

Aged biochar alters nitrogen pathways in bauxite-processing

2019.4.1 Bauxite-processing residue sand (BRS), represents the primary material used for constructing the perimeter walls of Alcoa's residue storage areas (Goloran et al., 2014, 2013) which is progressively rehabilitated as part of refinery closure (Gherardi and Rengel, 2003). ... Biomass harvest and plant and bauxite residue sand analysis.

Read More

COMPOSITION AND CHARACTERISTICS OF RED MUD: A

2017.12.12 Bauxite residue emerges as the major waste material during production of alumina from bauxite by the Bayer’s process. An alumina refinery built in Tayan, West Kalimantan has a production capacity of 300 thousand tons per year. It means that it will produce red mud or bauxite residue approximately 300 – 350 thousand tons per year and

Read More

Shifts in leaf N:P stoichiometry during rehabilitation in highly ...

2015.10.7 Large quantities of sodic and alkaline bauxite residue are produced globally as a by-product from alumina refineries. Ecological stoichiometry of key elements [nitrogen (N) and phosphorus (P ...

Read More

Soil pollution and toxicity in an area affected by emissions

2019.4.15 Soil pollution and toxicity have been investigated in the Gardanne area (southern France) at a range of sites around a recognized pollution source, a bauxite processing plant (BPP), and a power plant (PP). Soil samples were submitted to inorganic and organic analyses and tested for toxicity in two invertebrate models.

Read More

Aluminum Mineral Processing and Metallurgy: Iron-Rich Bauxite

2018.11.5 3. Iron-rich bauxite processing and metallurgy. Iron-rich bauxite ore usually contains over 40 wt% iron oxide [11, 12], huge reserves are found in Australia, Guinea, Brazil, Laos, Vietnam and China, but they have not yet been used effectively.It is worth noting that more than 1.5 billion tons of iron-rich bauxite resources have been explored

Read More

Bauxite Residues Processing – Geomega Resources Inc.

Bauxite Residues Processing. Bauxite residues is the largest waste by-product generated in the Bayer bauxite refining alumina production process. Large quantities of this caustic red mud are generated worldwide every year, posing environmental and safety challenges. Storage of bauxite residues is a challenge for alumina refineries with over 80 ...

Read More

Bauxite Ore Processing Plant - China Bauxite Ore Processing Plant

1 天前 Company Introduction: Henan King State Heavy Industry Machinery Co., Ltd which is a Large-sized enterprise, especially engaged in manufacturing Mining equipment, road construction material machinery, AAC equipment, Crushing machines and fertilizer equipment with a long history over 30 years, and enjoyed highly fame both at home and

Read More

The Bauxite Industry and Its Development SpringerLink

2023.10.25 The plant faced problems in the hydrometallurgical treatment of the bauxite, and this greatly reduced plant efficiency (Mines and Geology Division 1975; Davis 1989). The other bauxite companies mined haematitic bauxite, and from the 1940s had overcome their main processing challenges.

Read More

Physical Bauxite Processing: Crushing and Grinding of Bauxite

2022.1.23 The most common initial process step to feed an alumina refinery with bauxite is the crushing or sizing of the raw bauxite material that is extracted from the mine. The feed material is crushed or sized so that it is conveyable, as well as correctly

Read More

Bauxite Beneficiation Tailings Reprocessing

4 天之前 Processing: The commonly used beneficiation processes for bauxite are ore washing, flotation, magnetic separation, chemical beneficiation, etc., and the tailings can be treated by processes such as

Read More

Global Mass Balance of Bauxite Production Chain

2024.4.18 The former Vale’s bauxite processing plant, located 60 km from Paragominas, Brazil, was commissioned in March 2007. The plant receives raw bauxite ore from an open-pit mine, and performs a set of

Read More

Bauxite Processing Plant-SBM Industrial Technology Group

2024.4.1 Bauxite Processing Plant. Bentonite Processing Plant, Bentonite Grinding Mill. Talc Processing Plant, Talc Crushing and Grinding Equipment. Marble Grinding Mill,

Read More

(PDF) Chemical Processing of Bauxite: Alumina

2022.1.23 PDF This Chapter provides an introduction to the Bayer process and how the mineral composition of bauxites affects the process variants and the... Find, read and cite all the research you...

Read More

Mining and Refining – Process - International

The process stages are: 1. Milling. The bauxite is washed and crushed, reducing the particle size and increasing the available surface area for the digestion stage. Lime and "spent liquor" (caustic soda returned from the

Read More

Physical Bauxite Processing: Crushing and Grinding of Bauxite

2022.1.23 Abstract. The most common process step to feed an alumina refinery with bauxite is sizing of the raw bauxite material that is extracted from the mine. The first

Read More

Physical Bauxite Processing: Crushing and Grinding of

2022.1.23 To process the bauxite, the bauxite must be mined, crushed, and delivered to the refinery. The first step to reaching the refinery after mining the bauxite is crushing.

Read More

Bauxite Mining and Alumina Refining - PMC - National

2014.5.8 Abstract. Objective: To describe bauxite mining and alumina refining processes and to outline the relevant physical, chemical, biological, ergonomic, and

Read More

Bauxite Processing Handling Equipment

2024.2.13 EQUIPMENT. FEECO offers a variety of custom equipment and process solutions for the processing of bauxite. From processing bauxite for use in aluminum production, refractory, or

Read More

Vedanta Aluminium patents innovative breakthrough in bauxite

2023.11.6 This containment method prevents bauxite residue from inadvertently leaching into the groundwater. For this processing purpose, the company was the first in the country to establish a Bauxite Residue Processing Plant. With the new method implementation, this residue generation will be reduced further.

Read More

Impacts of greenwaste biochar on ammonia volatilisation from bauxite ...

2012.10.3 Background and Aims The objective of this study was to test the suitability of greenwaste biochar to aid nitrogen (N) retention in rehabilitated bauxite-processing residue sand (BRS). Methods Bauxite residue sand was collected from the Alcoa of Australia Pinjarra refinery. The pH of BRS was adjusted to values of 5, 7, 8 and 9 and

Read More

Alumina processing - Metso

Our alumina processing offering is based on our proven, reliable proprietary equipment portfolio and our comprehensive service expertise. We provide complete solutions for alumina refineries from bauxite to alumina, as well as plant upgrades. We are committed to innovation and continuous improvement and have a strong track record, having served ...

Read More

The Bayer Process: From Bauxite to Aluminum Hydroxide

2022.11.4 In the Bayer process, the basis for this is the different chemical solubility of the various oxides in caustic soda NaOH. Since the process is quite complicated, we will only mention the most important process steps here. The diagram of the process is shown in Fig. 20.2. The corresponding equipment in the aluminium oxide plant is marked in Fig ...

Read More

(PDF) Chemical Processing of Bauxite: Alumina and Silica

2022.1.23 The Bayer process is a chemical process for refining aluminium hydroxide, Al(OH) 3 from bauxite; this aluminium hydroxide is subsequently calcined to produce alumina, Al 2 O 3 . The basis of the ...

Read More

Bauxite Ore Processing Bauxite Ore Processing Equipment

About us. We,Star Trace Pvt. Ltd., established our operations in the year 1991, as one of the glorious ISO 9001:2008 certified manufacturers, exporters and suppliers of an unlimited collection of Industrial Separators Magnetic Equipment. Our product collection comprises of Magnetic Separators, Overband Magnets and Magnetic Roll Separators ...

Read More

Wet processing equipment CDE Asia

Read More

PT ANTAM Tbk Bauxite

Bauxite, the raw material for the production of alumina, was first discovered in 1924 at Kijang, Bintan Island, in the province of Riau, in northwestern Indonesia. Bauxite from Bintan Island has been mined and exported since 1935. In 1968 ANTAM acquired the mine. Thus, ANTAM is Indonesia's longest running producer of bauxite.

Read More

Hydro Partners with Wave to Recover Minerals from Red Mud

2023.2.22 Hydro’s Alunorte alumina refinery signed a contract with Wave Aluminium to build a plant in Brazil that will work to address the challenges of bauxite residue — also known as red mud. The new plant will process bauxite residue, aiming to recover commercially valuable materials. Bauxite residue is generated after the bauxite ore has

Read More

The processing of high silica bauxites - ScienceDirect

2009.8.1 The Bayer process is the principal method for the production of alumina from bauxite worldwide. The modern version of the process (developed in the 1880's) still maintains the key steps of dissolution of alumina-rich minerals into hot caustic solution, separation of the insoluble phases, followed by gibbsite precipitation and calcination of

Read More

Bauxite Processing Residue: A Critical Review of Its

2011.2.2 Abstract. Bauxite is processed in alumina refineries by the Bayer process in which Al-containing minerals are dissolved in hot NaOH. The insoluble solids (bauxite processing residue mud and sand) are washed, sometimes partially neutralized (using CO 2 or seawater treatment), and deposited in impoundments surrounding the refinery using

Read More

Global Mass Balance of Bauxite Production Chain

2024.4.18 The former Vale’s bauxite processing plant, located 60 km from Paragominas, Brazil, was commissioned in March 2007. The plant receives raw bauxite ore from an open-pit mine, and performs a set of

Read More

Surface charge characteristics and sorption properties of bauxite ...

2010.3.19 Bauxite-processing residue sand (BRS) is the primary growth medium used to rehabilitate Alcoa’s residue storage areas (RSAs) in south-west Western Australia. This material is typically coarse-textured, highly saline, highly alkaline, extremely sodic, and deficient in plant nutrients. To develop appropriate fertiliser strategies for optimising

Read More

Rotary Kiln Calcination Plant - Dolomite Calcination Plant

2 mt/hr up to 50 mt/hr. We stand as one of the leading manufacturers of Calcined Bauxite Rotary Kiln, manufactured from superior quality of raw materials. Some of the attributes of these machines are durability, robust, efficiency and cost effectiveness.These are fired with Petcoke, Oil, Gas and Coal Gas. We also provide dual fire option as well.

Read More

Crushing plant for bauxite processing sale in jamaica - LinkedIn

2023.11.30 The bauxite ore processing and crushing plants in Jamaica are integral to the island#8217;s economy and the global aluminum supply chain. Through efficient processing and responsible mining ...

Read More

Bauxite Ore Processing Bauxite Ore Processing Equipment

About us. We,Star Trace Pvt. Ltd., established our operations in the year 1991, as one of the glorious ISO 9001:2008 certified manufacturers, exporters and suppliers of an unlimited collection of Industrial Separators Magnetic Equipment. Our product collection comprises of Magnetic Separators, Overband Magnets and Magnetic Roll Separators ...

Read More

Bauxite Calcination Plant at Rs 8000000/piece Bauxite Processing ...

Bauxite Calcination Plant - Buy Bauxite Processing Plant at best price of Rs 8000000/piece by Kinc Mineral Technologies Private Limited. Also find product list from verified suppliers with contact number ID: 2532978448

Read More

Review on treatment and utilization of bauxite residues in

2009.12.8 Bauxite residue (red mud) is a solid waste produced in the process of alumina extraction from bauxite. More than 70 million tons of bauxite residue is generated annually. Presently, it is stored on land or in the ocean near alumina refineries. However, its high alkalinity is a potential pollution to water, land and air of close proximity.

Read More

Mining and Refining – Process - International

Bauxite is generally extracted by open cast mining, being almost always found near the surface, with processes that vary slightly depending on the location. Before mining can commence the land needs to be cleared of

Read More

Soil pollution and toxicity in an area affected by emissions

2019.4.15 Soil pollution and toxicity have been investigated in the Gardanne area (southern France) at a range of sites around a recognized pollution source, a bauxite processing plant (BPP), and a power plant (PP). Soil samples were submitted to inorganic and organic analyses and tested for toxicity in two invertebrate models.

Read More

Aged biochar alters nitrogen pathways in bauxite-processing

2019.4.1 Bauxite-processing residue sand (BRS), represents the primary material used for constructing the perimeter walls of Alcoa's residue storage areas (Goloran et al., 2014, 2013) which is progressively rehabilitated as part of refinery closure (Gherardi and Rengel, 2003). ... Biomass harvest and plant and bauxite residue sand analysis.

Read More

COMPOSITION AND CHARACTERISTICS OF RED MUD: A

2017.12.12 Bauxite residue emerges as the major waste material during production of alumina from bauxite by the Bayer’s process. An alumina refinery built in Tayan, West Kalimantan has a production capacity of 300 thousand tons per year. It means that it will produce red mud or bauxite residue approximately 300 – 350 thousand tons per year and

Read More

Shifts in leaf N:P stoichiometry during rehabilitation in highly ...

2015.10.7 Large quantities of sodic and alkaline bauxite residue are produced globally as a by-product from alumina refineries. Ecological stoichiometry of key elements [nitrogen (N) and phosphorus (P ...

Read More

Soil pollution and toxicity in an area affected by emissions

2019.4.15 Soil pollution and toxicity have been investigated in the Gardanne area (southern France) at a range of sites around a recognized pollution source, a bauxite processing plant (BPP), and a power plant (PP). Soil samples were submitted to inorganic and organic analyses and tested for toxicity in two invertebrate models.

Read More

Aluminum Mineral Processing and Metallurgy: Iron-Rich Bauxite

2018.11.5 3. Iron-rich bauxite processing and metallurgy. Iron-rich bauxite ore usually contains over 40 wt% iron oxide [11, 12], huge reserves are found in Australia, Guinea, Brazil, Laos, Vietnam and China, but they have not yet been used effectively.It is worth noting that more than 1.5 billion tons of iron-rich bauxite resources have been explored

Read More

Bauxite Residues Processing – Geomega Resources Inc.

Bauxite Residues Processing. Bauxite residues is the largest waste by-product generated in the Bayer bauxite refining alumina production process. Large quantities of this caustic red mud are generated worldwide every year, posing environmental and safety challenges. Storage of bauxite residues is a challenge for alumina refineries with over 80 ...

Read More

Bauxite Ore Processing Plant - China Bauxite Ore Processing Plant

1 天前 Company Introduction: Henan King State Heavy Industry Machinery Co., Ltd which is a Large-sized enterprise, especially engaged in manufacturing Mining equipment, road construction material machinery, AAC equipment, Crushing machines and fertilizer equipment with a long history over 30 years, and enjoyed highly fame both at home and

Read More

The Bauxite Industry and Its Development SpringerLink

2023.10.25 The plant faced problems in the hydrometallurgical treatment of the bauxite, and this greatly reduced plant efficiency (Mines and Geology Division 1975; Davis 1989). The other bauxite companies mined haematitic bauxite, and from the 1940s had overcome their main processing challenges.

Read More